Guangzhou Tianyuan Silicone Machine Technology Co., Ltd. is established in 2002, which specializes in designing and

manufacturing the LSR automatic injection molding machine as well

as the LSR mold, we mastered the core technology, the quality is

excellent! Our production technology is in the leading level in

China; we adopt the advanced integration design on our LSR machine,

and can supply personalized solutions for the customer. It is more

energy-efficient, easy to operate, the production speed is high.

TYM LSR machine is your best choice for saving the production cost

when you choose a machine.

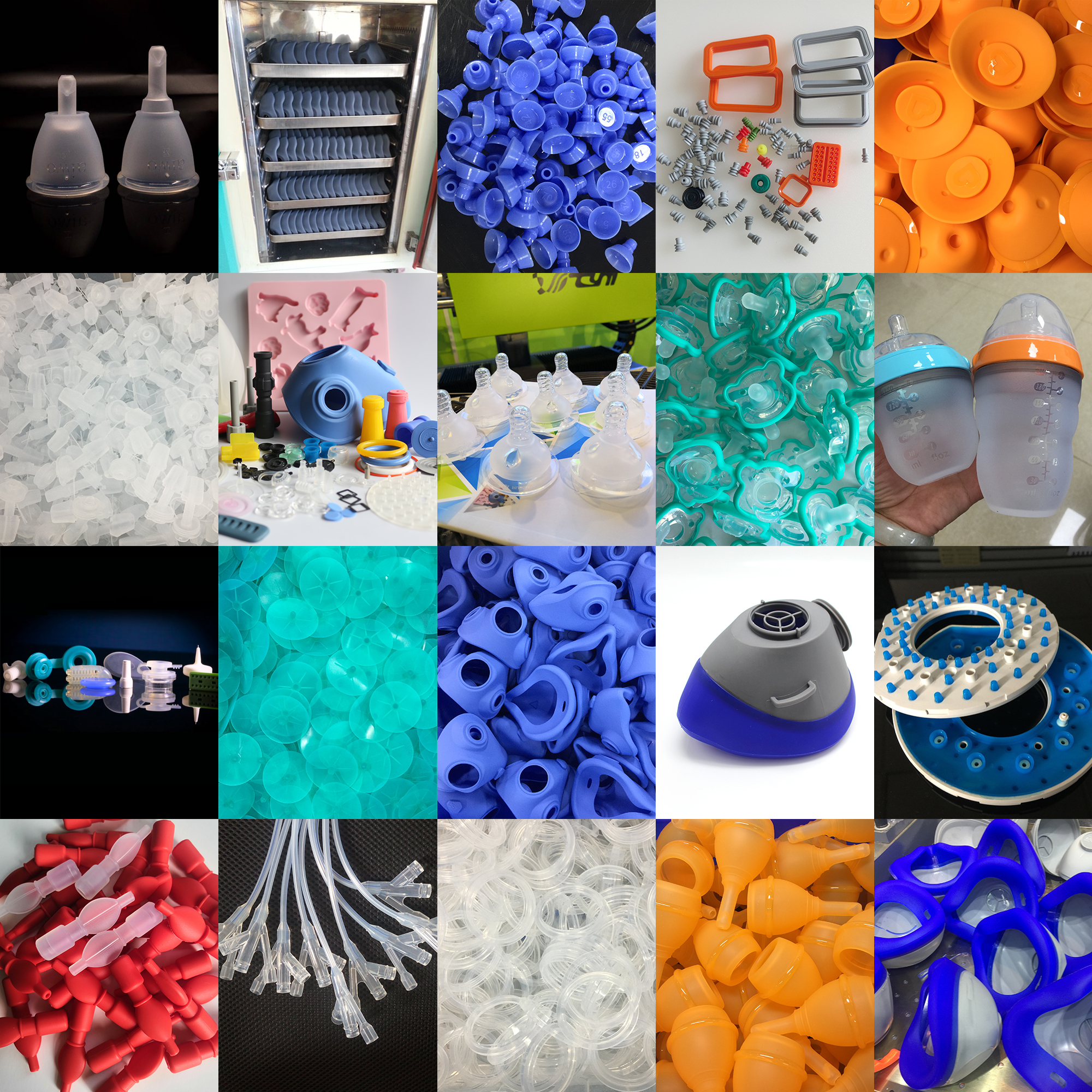

Our LSR injection molding machine is widely used in medical

industry, food industry, infant industry, diving industry,

insulator industry and other LSR production field. Furthermore,

with abundant technical strength,Tianyuan can design the LSR

injection molding equipment exactly based on the customer's

requirements, and can provide the turn-key solutions, such as the

LSR feeding machine, LSR injection molding machine, LSR mixing

system, color adding system, LSR mould and so on. In order to make

the machines to be highest quality and the most efficient, we

purchased the machine components from the famous manufactures in

Europe, Japan and Taiwan. with the high-quality, precise and

reliable LSR injection molding machine, our company successfully

help our customer produce the refined LSR products, and the cost

performance is the envy of the LSR industry.

Our Company Invests Large Fund And Brains To Research Products To

Fit The Demand Of The Market.With years of development, cust-omers

have been distributed in more than 40 countries and re-gions around

the world including USA, Germany, Spain, Brazil, Mexico,

Russia, Poland, England, Turkey, Italy, Saudi Arabia, Malysia,

Thailand, India, South Africa, Algeria, Egypt and so on. We also

sale in all major cities in China, provide customers with perfect

pre-sale and after-sale sales Ser-vice is what we 've been working

on!

High quality and in pursuit of perfection is our quality concept,

with “customers' development is the development of our company; our

company’s development is the staffs’ development” as our core

value, we’re willing to provide the most satisfactory service to

all customers!